Hauge Aqua Solutions AS proudly presents a new robust enclosed technology for industrial fish farming. The aim of the new technology is to enable sustainable growth in the aquaculture industry.

Addressing key challenges through New Innovative Technology

Hauge Aqua's believes that the current production platform based on open pen systems is too weak to sustain significant growth, recognised environmental performance and societal expectation. Hauge Aqua's ambition is to provide a trustworthy and competitive alternative production platform.

By our excellent team and collaborating partners, we offer the industry a fully contained system in which we address many of current costly challenges that apply in today's farming.

Summarised

- The sheltered workplace addresses health and safety for the staff by eliminating many high-risk operations

- The water intake is located at the bottom of the unit at a depth where the salmon louse is not normally found.

- Due to the level-separated intake- and outflow of water the pen to pen, as well as site to site infection pressure are significantly reduced

- The design, water flow and stable environment inside the egg will facilitate fish welfare and performance

- The closed containment and feeding regimes enable more accurate feeding without loss of uneaten feed

- The robust unit will reduce and maybe eliminate risk of escape during sea phase

- The retaining of particulate faeces, will reduce organic discharge and provide an opportunity to increase production per site

- The unit separates and shelters the fish against predators

The Geometrical Shape

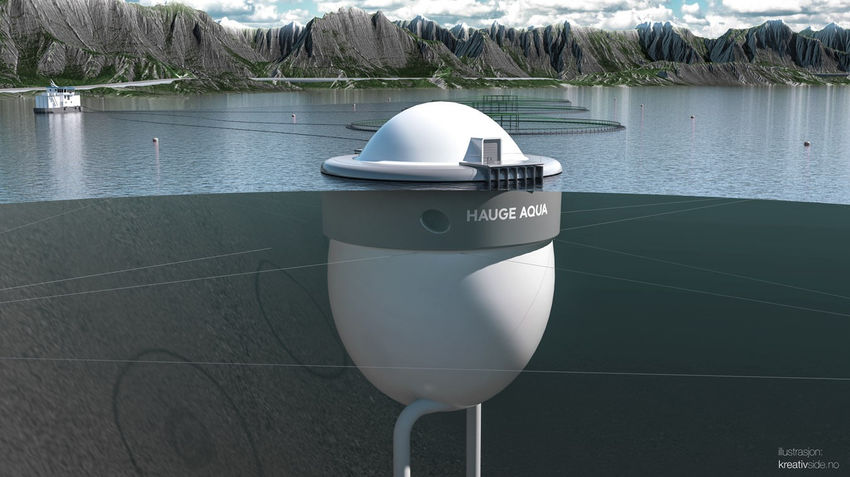

The shape of the new robust and enclosed tank is that of an egg built in composite sandwich. The shape provides a complete double curved surface. Ninety percent of the tank is submersed and not visible during operation, whereas ten percent is above the water and filled with ventilated air. Inside the tank, a central tube may be placed and may stiffen off the structure vertically. The shape diverts external forces and makes a robust geometrical structure. Likewise, The egg structure is fully enclosed with a dome protecting against flushing of waves into the unit. Also, it provides a sheltered and safe working area for personnel.

Anchoring system

The egg targets to replace the large circular net pens used in today's typical site set-up. Likewise, it is designed to be supported by existing infrastructure such as the feed barge and electrical power. It is towed into the anchoring frame while still empty of water. Once inside the frame and plugged to power, valves are opened in the bottom and gradually the egg will sink until it reaches its operating position. The tank is then moored horizontally into existing mooring system in a farm.

Functionality

The unique water flow enables the system to draw inlet water segregated from where outlet water is released. The inlets are located in the bottom of the egg. Water enters by the use of two main pumps that suck water from 17-38 metres depending on the size of the unit. The water is put in a circular movement by circulation devises and eventually to the top where it exit the tank 3-6 meters below surface. Water quality and flow-rate can be controlled, ensuring steady oxygen levels and also sufficient evacuation of carbon dioxide. The bottom entry avoids lice larvae to enter the unit since salmon lice larvae natural habitat predominantly is in the top layer. The water inlet and outlet is double-secured so that escape is not possible.

The feed is either supplied from a on-unit feed storage or through barge-based regular automatic feeders as used on sites today. Feed distributors inside the unit may be opted by customer choice. The system enables good feeding and waste control.

A tricky part of farming in closed containment is crowding, grading and harvesting the fish inside. In the video this is illustrated by a collapsable fish grid hauled up and down while centered by the central column. After having spent much resources in design of the grid, we have simplified the crowding and harvesting process.

Collection of Organic Waste

Improving the control of feed spillage and collection of organic solids (fish faeces), significantly improves the industry use of resources.

Feeding accurately is alleviated by use of a contained system. The horisontal and upwards water current keeps the feed pellets accessible for the fish for a longer period than in open systems where uneaten feed drifts out of the pen by the current.

The shape of the egg will increase the speed of the water and hence vertical and centripetal forces on particles as the water flows to the top of the tank. These forces may be utilised to trap particles and retain them from being discharged. While most of the water is discharged through main valves, the technology aims to filtered off solid fish faeces in the bottom pit of the unit by a constant extraction of water which is brought to particle filters. Organic solids (fish faeces and uneaten food if necessary) are collected in the tank and can either be recylcled (feed) or be used as a valuable resource.

Operating and controlling the environment

Light is possible to control 24 hours a day inside the egg. The fish may be supplied with the ideal amount and wavelength of light. As opposed to open net pens where oxygen can vary by season, upwelling and tide, the egg provides an opportunity to keep oxygen at adequate levels at all times.

The temperature profile of deeper layers of the fjords provides less temperature variation than in surface. This supports better winter growth in the egg than in open cages, pobably lower growth rate during Spring, but also avoids the peak temperature weeks during summer. However, in a the fjords of Western Norway temperature sum (sum of day degrees) is not very different with deep water intake compared to surface. In other words, we expect growth to become more even which also would apply to harvest profile.

Utilization of Sites

The robust egg-shape and material makes it suitable for today's locations. Because of the reduction of discharge of nutrients, due to the aforementioned collection of fish faeces, one may produce more fish per site within the same discharge consent. The fish farmers can operate many eggs from the same land base or feed barge. This enables more efficient use of designated aquaculture area than today.

The egg opens up for new areas for fish farming both because lice and escapes no longer represent an unacceptable risk.

Health and safety

Health and safety of personnel in daily operations of the unit is important. The most important contribution to health and safety is the significant reduction in high-risk operations.

Apart from this, the docking area is well defined and secured. While inside the unit, the operator is sheltered from waves, splash, rain and wind as well as enjoying a comfortable air temperature.